|

|

|

|

River Galfan Gabion Mattress 60*80mm Mesh

|

Product Details:

Payment & Shipping Terms:

|

| Product Name: | Galfan Gabion Basket Wall 2x1x1m Gabion Wire Mesh Box 60 X 80mm Opening | Material: | Low Carbon Steel Wire, Galvanized Wire, PVC Coated Iron Wire |

|---|---|---|---|

| Standard: | ASTM A975, EN | Finish: | Galvanized, PVC Coated |

| Opening: | 60x80, 80x100, 100x120mm | Mesh Wire Diameter: | 2.0mm, 2.2mm, 2.7mm |

| Selvedge Wire Diameter: | 2.7mm, 3.0mm, 3.4mm | Gabion Box Length: | 1m, 1.5m, 2m, 3m, 4m |

| Gabion Box Width: | 0.5m, 1m | Gabion Box Height: | 0.5m, 1m |

| Packaging: | In Bundles | Application: | For Slope Support, Foundation Pit Support, Mountain Rock Hanging Net With Shotcrete, Slope Planting, Railway And Highway Isolation Block |

| Highlight: | River Galfan Gabion Mattress,60x80mm Mesh Gabion Mattress,River Gabion Box Wire Mesh |

||

| Attribute | Value |

|---|---|

| Product name | Galfan Gabion Basket Wall 2x1x1m Gabion Wire Mesh Box 60 X 80mm Opening |

| Material | Low Carbon Steel Wire, Galvanized Wire, PVC Coated Iron Wire |

| Standard | ASTM A975, EN |

| Finish | Galvanized, PVC Coated |

| Opening | 60×80, 80×100, 100×120mm |

| Mesh wire diameter | 2.0mm, 2.2mm, 2.7mm |

| Selvedge wire diameter | 2.7mm, 3.0mm, 3.4mm |

| Gabion Box Length | 1m, 1.5m, 2m, 3m, 4m |

| Gabion Box Width | 0.5m, 1m |

| Gabion Box Height | 0.5m, 1m |

| Packaging | in Bundles |

| Application | for slope support, foundation pit support, mountain rock hanging net with shotcrete, slope planting, railway and highway isolation block |

The ecological gabion box process only needs to load the stone into the cage to seal it, requiring no special technology, water, or electricity.

The combination of engineering and plant measures effectively prevents soil erosion, with fast landscape effects that appear more natural and richer.

Ecological gabion box lifespan of up to decades, generally requiring no repair. Used in major projects like the Yangtze River Huangshi section berm project and Three Gorges Sanduping shore protection project.

| Standard Mesh dimensions (X×Y) | Mesh wire Gl dia (mm) | Selvedge wire Gl dia (mm) |

|---|---|---|

| 60×80MM | 2.0 | 2.7 |

| 80×100MM | 2.2 | 3.0 |

| 100×120MM | 2.7 | 3.4 |

| Length (m) | Width (m) | Height (m) |

|---|---|---|

| 1 | 0.5 or 1 | 0.5 or 1 |

| 1.5 | 1 | 0.5 or 1 |

| 2 | 0.5 or 1 | 0.5 or 1 |

| 3 | 1 | 0.5 or 1 |

| 4 | 1 | 0.5 or 1 |

| Length (m) | Width (m) | Height (m) |

|---|---|---|

| 3 | 2 | 0.17, 0.23 or 0.30 |

| 6 | 6 | 0.17, 0.23 or 0.30 |

Excellent low-carbon steel wire, diameter: 2.0mm-4.0mm, tensile strength: no less than 380Mpa. Surface protection through hot galvanization (max. 300g/m2) according to customer demands.

New material with corrosion resistance 3 times of traditional galvanization; diameter: 2.0mm-4.0mm; tensile strength: no less than 380Mpa.

Low-carbon steel with PVC/PE coating for high pollution environments. Available in different colors to blend with surroundings.

Alloy steel wire with PVC/PE coating offering superior protection in harsh environments with color options.

Gabions are molded once with inseparable edge, end and bottom plates (except cover plates). Length/width tolerance (±5%), height tolerance (±5%). Interior divided by clapboards every meter.

Assembly mode with separate components (cover plates, edge plates, etc.) wound by spiral steel wire. All edge wire uses thick wire for enhanced strength.

Gabion Box Wire Mesh is packaged in bundles. Panels are woven, folded into bundles, fixed with binding belts for optimal container space utilization. When used, bundles are folded and assembled with binding wire, then filled with stones to form complete Gabion Boxes.

Gabions must be filled with rock ranging between 100mm and 250mm (5% variation allowed). Oversize rock ≤300mm, undersize ≥100mm. Rocks must be hard, angular to round, durable and weather-resistant. Careful placement ensures polymer coating isn't damaged, with visible faces hand-placed for appearance.

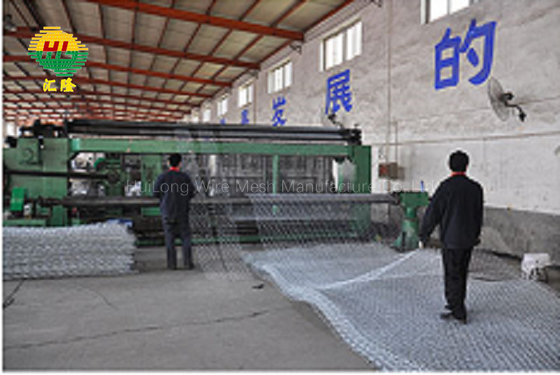

- 18-year factory with registered trading company for comprehensive product sourcing

- Strict quality control from raw materials to final products

- Professional international trade team providing excellent service

- Quality Assurance Department ensuring international standards

- 24-hour response time for any issues, with resolution within 72 hours

- Free samples available

- Custom specifications available

Contact Person: LV

Tel: 8613780284669

-

100x120mm Gabion Box Stone Cage

-

PVC Coated Hexagonal Gabion Box

-

Flood Control Stone Filled Wire Cages

-

ASTM A975 Gabion Box Wire Mesh , Galvanized 10mm Gabion Stone Basket

-

Twist Wire Mesh Stone Cages , PVC Coated Retaining Wall Cages 1m Height

-

Hot Dipped Galvanized Gabion Box Wire Mesh Heavy Duty 2x1x1m